Replacing R22 dryers

What is R22 and why is it a problem?

R22 (chlorodifluoromethane) is a hydrochlorofluorocarbon (HCFC) once widely used in refrigerant dryers and air conditioning systems. It was prized for its cooling efficiency, helping dryers condense and remove moisture from compressed air.

But R22 comes with serious environmental drawbacks. With a GWP (Global Warming Potential) of 1,810, it’s a potent greenhouse gas and has therefore been phased out globally. In the UK and EU, it has been banned in new equipment since 2010 and banned within servicing since 2015.

Using R22 dryers can also be expensive as they incur higher servicing costs and parts are limited. Being less efficient than modern alternatives, they consume significantly more energy and have higher running costs.

If you have a Carbon Reduction Plan in place, using R22 equipment will have a huge impact on your environmental reporting and replacement should be a priority.

Today’s compressed air dryers offer better performance and a lower carbon footprint, but why are they needed within a compressed air system at all?

A dryer is a vital component of a compressed air system because it ensures the air delivered is clean, dry, and suitable for use in sensitive equipment and processes. When air is compressed, its temperature rises, and as it cools, moisture condenses from the air. This water vapor, if left untreated, can cause corrosion in pipelines, damage tools, contaminate products, and lead to costly downtime or repairs. A dryer removes this residual moisture, protecting the integrity of the system and improving overall efficiency.

A typical compressed air set-up includes:

- Air compressor → compresses ambient air

- Aftercooler → removes bulk moisture

- Dryer → eliminates remaining water vapor

- Filters → traps oil and particles

- Receiver tank → stores clean, dry air

Choosing the right dryer

There are several factors to consider when selecting a dryer, whether it’s as a replacement or introducing it into an existing compressed air system. These include:

- Required dew point

- Flow rate and pressure

- Ambient conditions

- Energy efficiency and maintenance needs

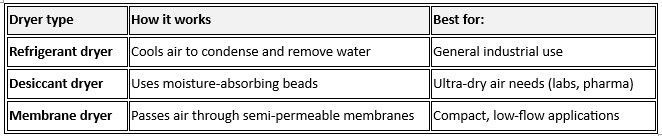

For general workshops, a refrigerant dryer may be ideal. For ultra-dry applications like labs or electronics, a desiccant dryer might be better suited.

Types of dryers and their applications

Hi-Line Tundra dryers

For organisations seeking a reliable, energy-efficient, refrigerant dryer, Hi-Line’s Tundra range offers a future-proof solution. These dryers use eco-friendly refrigerants:

Tundra 22 to 115: uses R513a which is a low-GWP (Global Warming Potential) refrigerant, making it a more environmentally friendly choice for smaller units.

Tundra 175 and above: uses R407c which has a higher GWP than R513a but is commonly used in larger refrigeration systems and offers good energy efficiency.

With features like scroll compressors, variable speed fans, and direct expansion technology, Tundra dryers deliver consistent dew points and robust performance — all while meeting current UK and EU regulations.

More info on our range of Tundra dryers can be found here.

Whether you're operating in a general workshop, a food production facility, or a high-precision manufacturing environment, maintaining dry compressed air is essential. It helps extend the lifespan of equipment, ensures consistent product quality, and supports compliance with industry standards. By integrating a dryer into your setup, you’re not just removing water — you’re safeguarding your entire operation.

BCAS can recommend the right dryer for your specific needs. Contact the team to discuss your options.